Push-Back Pallet Rack

Push-back racking from Culver Equipment delivers high-density storage and fast pallet access for today’s most demanding warehouses. Our push-back systems combine gravity-driven technology with maximum selectivity—ideal for fast-moving SKUs, food, beverage, cold storage, and manufacturing environments.

What is Push-Back Racking?

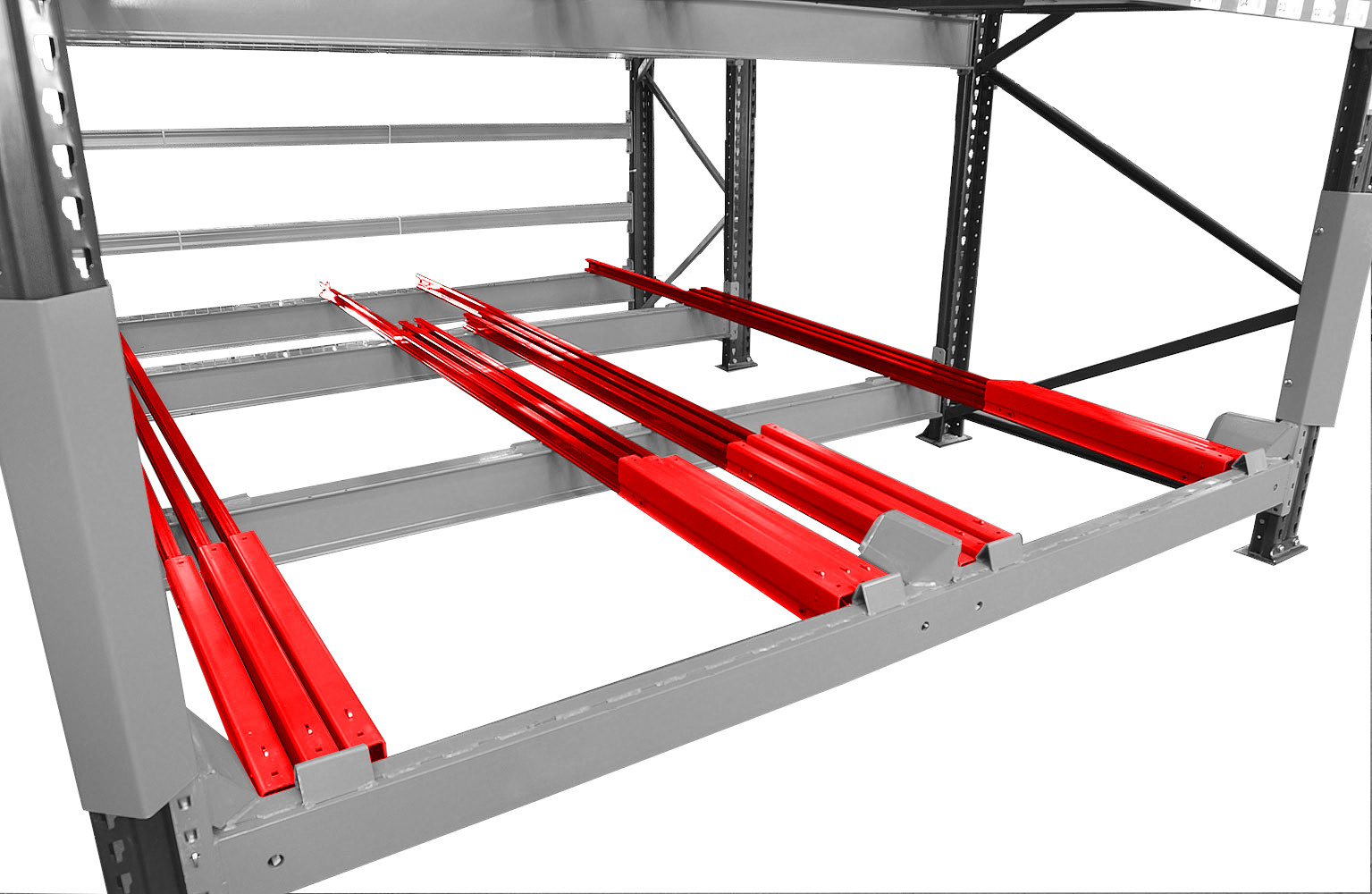

Push-back pallet racking is a high-density, gravity-fed storage system that maximizes space and efficiency in your warehouse. Pallets are loaded onto rolling carts, which move along inclined rails. As pallets are loaded, each cart is pushed backward; as pallets are unloaded, the next cart moves forward automatically—offering up to 50% more storage than standard selective racking.

- High Storage Density: Store more pallets in less space, reducing aisle count and maximizing cubic storage.

- SKU Selectivity: Retain multiple pick faces and access to different SKUs per lane—ideal for fast product rotation.

- Forklift Accessible: Operators never need to enter the rack—improving safety and reducing rack damage.

- Gravity Driven: Pallets automatically advance to the pick face, streamlining loading and unloading.

- Custom Configurations: Systems can be tailored for 2–6 pallets deep, multiple heights, and various cart/wheel options.

- Low Maintenance: Heavy-duty carts with sealed bearings for long life and minimal upkeep.

- Integration: Easily integrates with other rack systems—perfect for food, beverage, logistics, and cold storage.

How Push-Back Racking Systems Work

Gravity-Fed Rails & Carts

Inclined rails and rolling carts use gravity to move pallets forward, always keeping products at the aisle for quick retrieval.

Learn MoreIndependent Lanes

Each push-back lane operates independently—store multiple SKUs per bay and increase picking efficiency.

Learn MoreCustomizable Carts

Carts are tailored by color, size, mesh, wheels, profile, and finish for your unique pallet and environment needs.

Learn MoreSeamless Integration

Push-back racks can combine with selective, drive-in, or flow systems to optimize every area of your warehouse.

Learn MorePush-Back Racking Applications & Advantages

Food & Beverage / Grocery

Boost SKU density and product turnover for perishable and high-volume goods in a compact footprint.

DetailsCold Storage & Freezers

Push-back racking is ideal for refrigerated, freezer, and temperature-controlled warehouses—custom finishes available.

DetailsManufacturing & Logistics

Optimize parts, work-in-process, and inventory storage—maximize space and workflow efficiency.

DetailsE-commerce & Retail

Accommodate high-turn SKUs and rapid order picking—perfect for fast-moving, high-volume fulfillment.

DetailsGravity-Fed Rails & Rolling Carts

Push-back racking uses sloped rails with robust rolling carts. When a pallet is loaded, each cart is pushed back, creating deep storage lanes. As pallets are unloaded, gravity brings the next pallet forward for easy access, increasing speed and reducing aisle congestion.

Independent Storage Lanes

Each push-back lane operates independently, so you can store multiple SKUs within the same rack bay. There’s no need to move blocking pallets, giving you more selectivity and flexibility than drive-in racking.

Customizable Carts

Push-back carts are engineered for your pallets—choose color, mesh supports, size, low-profile, heavy-duty wheels, finish, and protective covers. Options for freezer, food, or special environments available.

Seamless Integration

Combine push-back racking with selective, drive-in, or flow racking for a complete warehouse solution. Our experts design layouts for maximum space and workflow efficiency.

Food & Beverage / Grocery

Push-back racking is perfect for food processors, grocery warehouses, and beverage distributors. Store more SKUs per aisle and keep products easily accessible, fresh, and safe.

Cold Storage & Freezer Applications

Cold storage facilities benefit from push-back’s high density and selectivity. Custom finishes (like galvanized or stainless steel) withstand low temperatures and humidity, making systems reliable and long-lasting.

Manufacturing & Logistics

Manufacturers and logistics hubs use push-back racks for storing raw materials, finished goods, or components—minimizing aisle space and speeding up operations in busy production environments.

E-commerce & Retail

Keep fast-moving SKUs organized and ready to pick. Push-back racks are a favorite for e-commerce fulfillment, big-box retail, and any operation with high SKU variety and quick turnaround needs.